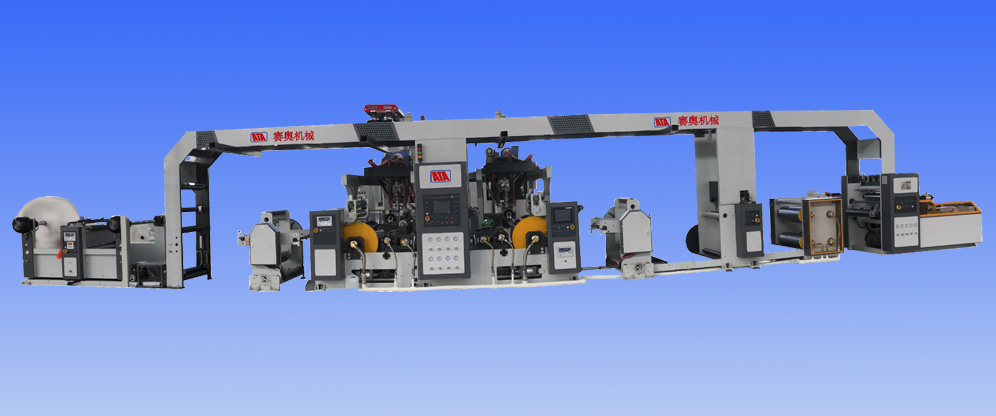

Laminating width 200-800mm

Mould head width 900mm

Laminating line speed 236m/min

|

Pos |

Description |

|

|

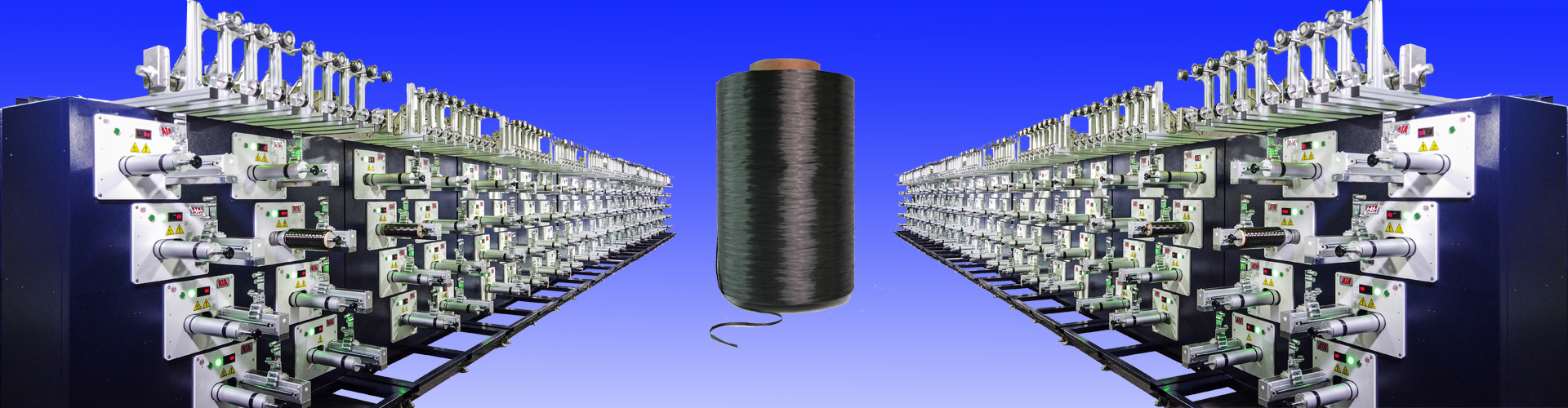

2 |

Extruder(elevated type) |

|

|

|

1)screw |

separation type |

|

|

screw dia |

75mm(2pcs) |

|

|

screw material |

38CrMoAlA(2pcs) |

|

|

extrusion motor |

22kw Siemens(2sets) |

|

|

inverter |

22kw Germany ABB(2sets) |

|

|

caremic heater |

each 30kw 1set |

|

|

auto temp-controller |

Omron(8pcs) |

|

|

thermocouple |

Omron(8pcs) |

|

|

advance and retreat motor |

1.5kw(2sets) |

|

|

journey switch |

2pcs |

|

|

fast Column Screen Change Filter |

2pcs |

|

|

Filter heater |

8kw(2pcs) |

|

|

filter auto temp-controller |

Omron(2pcs) |

|

|

filter auto thermocouple |

Omron(2pcs) |

|

|

auto loader |

2pcs |

|

|

automatic Lubrication Reducer for Hard Gear Surface Grinding |

2pcs |

|

|

worm and worm gear reducer |

2pcs |

|

|

main unit synchronous belt |

2sets |

|

|

|

|

|

2 |

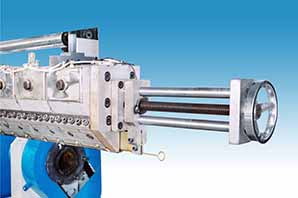

Mould |

|

|

|

T type die |

inner heating(2pcs) |

|

|

die material adjustable |

handwheel adjustable plugboard 200-1000 |

|

|

die inner heating |

each 6kw(2sets) |

|

|

die material |

5 chromium nickel molybdenum |

|

|

die auto temp-controller |

Omron(10pcs) |

|

|

die thermocouple |

Omron(10pcs) |

|

|

|

|

|

1 |

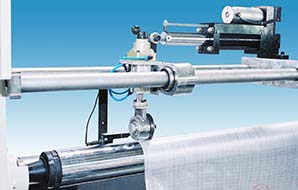

First feeding machine(semi-automatic roll change (fully-automatic tention) |

|

|

|

Movable guide rail of double-position unwinding frame (unwinding diameter 1400MM) |

|

|

|

unwinding shaft |

3〞2pcs |

|

|

pneumatic plug |

2pcs |

|

|

pneumatic brake |

Italy ER 75kg(2pcs) |

|

|

tension sensor |

KAIRUIDA(2pcs) |

|

|

tension controller |

Mitsubishi (1pcs) |

|

|

EPC edge control |

Aibo (1pcs) |

|

|

cloth connection rubber roller |

1pcs |

|

|

cloth connection steel roller |

1pcs |

|

|

cloth connection cylinder |

QGB 50×75(2pcs) |

|

|

heating drying device |

1 set |

|

|

|

|

|

1 |

Lamination machineⅠ |

|

|

|

mirror big cold roller |

diameter 600mm 1pcs |

|

|

sillicon roller |

diameter 250mm 75°anti-adhesion |

|

|

spiral cooling |

1pcs |

|

|

compressed roller |

spiral cooling 1pcs |

|

|

tension roller |

1pcs |

|

|

rotate joint |

2″ 2pcs 1″ 4pcs |

|

|

Roller transmission device |

1set |

|

|

compression cylinder |

QGB 125×80(2pcs) SC80X80(2pcs) |

|

|

Double position BOPP color film feeder (max diameter1000mm) |

1set |

|

|

powder break |

5kg Lanling(2pcs) |

|

|

tension sensor |

KAIRUIDA(2pcs) |

|

|

tension controller |

Mitsubishi (1pcs) |

|

|

air extension shaft |

2pcs |

|

|

base flating device |

1 set |

|

|

|

|

|

1 |

Laminating machine II |

|

|

|

mirror big cooling roller |

diameter 600mm 1pcs |

|

|

sillicon roller |

diameter 250mm 75°anti-adhesion |

|

|

spiral cooling |

1pcs |

|

|

pressing roller |

spiral cooling 1pcs |

|

|

rotate joint |

2″ 2pcs 1″ 4pcs |

|

|

inverter |

7.5KW Germany ABB 1pcs |

|

|

compression cylinder |

QGB 125×80(2pcs) |

|

|

SC80X80 |

2pcs |

|

|

Double position BOPP color film feeding (max diameter1000mm) |

1set |

|

|

powder break |

5kg Lanling(2pcs) |

|

|

tension sensor |

KAIRUIDA(2pcs) |

|

|

tension controller |

Mitsubishi 1pcs |

|

|

air extension shaft |

Φ74(2pcs) |

|

|

photo sensor tracking auto cutting device |

2pcs |

|

|

side cutting shaft |

1pcs |

|

|

Side cutting knife base (include cylinder,air control valve) |

2sets |

|

|

waste material fan |

2.2kw 1set |

|

|

|

|

|

2 |

BOPP film double side automatic register |

|

|

|

photo sensor tracking device |

1set |

|

|

maixin servo motor |

2sets |

|

|

maixin servo controller |

2sets |

|

|

photo sensor |

Bangna USA(2pcs) |

|

|

PLC |

Siemens 1set |

|

|

man-machine interface |

Siemens 1set |

|

|

membrane Alarm Device |

Siemens 1set |

|

|

|

|

|

1 |

Forming device |

|

|

|

1)forming roller |

diameter 300mm 4sets |

|

|

2)rotate joint |

1” 8sets |

|

|

|

|

|

1 |

Winding machine |

|

|

|

counting device |

1set |

|

|

Double position big roller vibration winding frame(changing without stop) |

1set

|

|

|

winding roller |

1pcs |

|

|

automatic tension roller device (include Precision potentiometer etc) |

1set |

|

|

rubber press roller |

1pcs |

|

|

|

|

| Laminating width | 200-800mm |

| Laminating thickness | 0.012-0.03mm |

| Laminating line speed | 236m/min |

| Screw diameter | 75mm |

| Screw length | 2600mm |

| Screw rotate speed | 100r/min |

| Max extrusion | 130kg/h(single machine) |

| Roller length | 900mm |

| Mould head width | 900mm |

| Winding&unwinding max diameter | 1400mm |

| Unwinding EPC auto edge control journey | ±100mm |

| Total power | 100kw |

| Gas flow | 0.6m3/min |

| Dimension | (17.5L×7.5W×2.8H)m |

| Overall weight | 22mt |

| Machine color | Standard color |

| Power | Three phase 380v+single phase 220v,50HZ |

HOME

HOME